Prilagođena izrada, skladišna radionica, izgradnja čelične konstrukcije

Prilikom detaljiranjamontažna čelična konstrukcija,važno je uzeti u obzir sljedeće ključne elemente:

Strukturni raspored: To uključuje raspored i pozicioniranje čeličnih greda, stupova i drugih elemenata kako bi se formirao koherentan i stabilan okvir.

Specifikacije materijala: Detaljni opis točnih specifikacija čelika koji će se koristiti, uključujući njegovu vrstu, veličinu i druga relevantna svojstva, kako bi se osigurala strukturna cjelovitost i sigurnost.

Spojevi: Detaljan opis spojeva između različitih čeličnih komponenti, kao što su zavarivanje, vijčano spajanje ili druge metode spajanja, kako bi se osigurala sigurna i stabilna konstrukcija.

Izrada nacrta: Izrada detaljnih i točnih nacrta koji će voditi proces izrade, uključujući dimenzije, tolerancije i ostale zahtjeve.

Sigurnosna razmatranja: Osiguravanje da čelična konstrukcija bude u skladu sa svim relevantnim sigurnosnim i građevinskim propisima, uključujući razmatranja nosivosti, otpornosti na vatru i strukturne stabilnosti.

Kompatibilnost s drugim sustavima: Koordinacija detalja čelične konstrukcije s drugim građevinskim sustavima, kao što su mehaničke, električne i arhitektonske komponente, kako bi se osigurala besprijekorna integracija.

Ovi detalji su ključni za uspješno projektiranje i izgradnju čelične konstrukcije te ih treba pažljivo planirati i izvesti kako bi se postigla sigurna, učinkovita i izdržljiva zgrada.

| Naziv proizvoda: | Čelična zgrada Metalna konstrukcija |

| Materijal: | Q235B, Q345B |

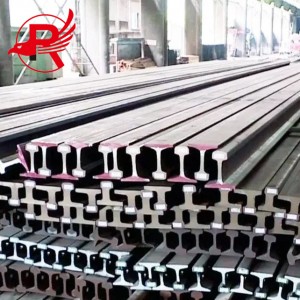

| Glavni okvir: | Čelična greda u obliku slova H |

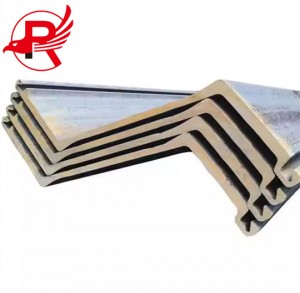

| Golica: | Čelična greda u obliku C, Z |

| Krov i zid: | 1. valoviti čelični lim; 2. sendvič paneli od kamene vune; |

| Vrata: | 1. Rolo vrata 2. Klizna vrata |

| Prozor: | PVC čelik ili aluminijska legura |

| Donji izljev: | Okrugla PVC cijev |

| Primjena: | Sve vrste industrijskih radionica, skladišta, visokih zgrada |

PROCES PROIZVODNJE PROIZVODA

DEPOZIT

čelična konstrukcijaTvorničke zgrade općenito su prostorni sustav sastavljen od krovnih konstrukcija, stupova, kranskih greda (ili rešetki), raznih nosača, zidnih okvira i drugih komponenti, kao što je prikazano na slici. Ove komponente mogu se podijeliti u sljedeće kategorije prema njihovim funkcijama:

1. Horizontalni okvir

2. Krovna konstrukcija

3. Sustav podupiranja (djelomična podupora krova i funkcija podupiranja stupova: nosivi spoj)

4. Greda dizalice i kočna greda (ili kočna rešetka)

5. Zidni stalak

PROJEKT

Naša tvrtka za čelične konstrukcije poduzela je brojne projekte čeličnih konstrukcija za američko i jugoistočnoazijsko tržište, pokrivajući ukupnu površinu od približno 543 000 četvornih metara i koristeći oko 20 000 tona čelika. Nakon završetka, ovi će projekti postati sveobuhvatni kompleksi čeličnih konstrukcija koji će integrirati proizvodnju, životni prostor, urede, obrazovanje i turizam.

INSPEKCIJA PROIZVODA

Čvrstoća i trajnost: Čelične konstrukcije nude visoku čvrstoću i trajnost, što omogućuje projektiranje s velikim rasponima i otpornost na utjecaje okoline poput vjetra i seizmičke aktivnosti.

Manja težina: Čelik je lakši od mnogih drugih građevinskih materijala, što može dovesti do smanjenih zahtjeva za temelje te lakšeg transporta i montaže.

Brzina gradnje: Čelične konstrukcije mogu se prefabrikovati izvan gradilišta, što dovodi do bržeg vremena gradnje i smanjenih potreba za radnom snagom na gradilištu.

Fleksibilnost u dizajnu: Čelik omogućuje širok raspon arhitektonskih dizajna i može se prilagoditi velikim otvorenim prostorima bez potrebe za međustupovima.

Održivost: Čelik je visoko reciklabilni materijal, a njegova upotreba u građevinarstvu može doprinijeti održivim građevinskim praksama.

Isplativost: Brzina gradnje, trajnost i smanjeni zahtjevi za održavanje čine čelične konstrukcije isplativom opcijom za mnoge građevinske projekte.

PRIJAVA

Slučaj zgrade od čelične konstrukcijeimaju širok raspon primjena u raznim industrijama i sektorima, uključujući:

- Industrijsko skladištenje: Čelična skladišta se obično koriste za skladištenje sirovina, gotovih proizvoda, opreme i strojeva u proizvodnim i industrijskim pogonima.

- Distribucijski centri: Ove su strukture idealne za distribucijske centre kojima je potreban veliki, otvoreni prostor za skladištenje i upravljanje zalihama.

- Logistika i lanac opskrbe: Čelična skladišta igraju vitalnu ulogu u industriji logistike i lanca opskrbe, osiguravajući učinkovito skladištenje i rukovanje robom za pravovremenu distribuciju.

- Maloprodaja i e-trgovina: Trgovci na malo i tvrtke za e-trgovinu često koriste čelična skladišta kao centre za ispunjavanje narudžbi za skladištenje, sortiranje i otpremu proizvoda kupcima.

- Poljoprivreda i poljoprivreda:Projektiranje čeličnih konstrukcijakoriste se za skladištenje poljoprivredne opreme, strojeva i proizvoda, kao i kao sklonište za stoku.

- Automobilska industrija: Čelična skladišta koriste se za skladištenje dijelova vozila, komponenti i gotovih vozila u automobilskoj industriji.

- Hladno skladištenje i hlađenje: Skladišta sa čeličnim konstrukcijama mogu biti posebno dizajnirana za hladno skladištenje i hlađenje, kao što je skladištenje kvarljive robe i prehrambenih proizvoda.

- Proizvodni pogoni: Čelična skladišta integrirana su u proizvodne pogone za skladištenje sirovina, zaliha u tijeku i gotovih proizvoda.

- Građevinski i građevinski materijal: Skladišta se koriste za skladištenje građevinskog materijala, kao što su čelične grede, cement, cigle i alati, za građevinske projekte.

- Vlada i vojska: Čelična skladišta koriste vladine agencije i vojska za skladištenje, logistiku i operacije hitne pomoći.

PAKIRANJE I DOSTAVA

Pakiranje:Prema vašim zahtjevima ili najprikladnijem.

Dostava:

Odaberite odgovarajući način prijevoza: Ovisno o količini i težini čelične konstrukcije, odaberite odgovarajući način prijevoza, kao što su kamioni s ravnom platformom, kontejneri ili brodovi. Uzmite u obzir čimbenike poput udaljenosti, vremena, troškova i svih regulatornih zahtjeva za prijevoz.

Koristite odgovarajuću opremu za dizanje: Za utovar i istovar čelične konstrukcije koristite odgovarajuću opremu za dizanje poput dizalica, viličara ili utovarivača. Osigurajte da korištena oprema ima dovoljan kapacitet za sigurno rukovanje težinom šipova.

Osigurajte teret: Pravilno osigurajte zapakirani hrpu čelične konstrukcije na transportnom vozilu pomoću remena, učvršćivača ili drugih prikladnih sredstava kako biste spriječili pomicanje, klizanje ili pad tijekom prijevoza.

SNAGA TVRTKE

Proizvedeno u Kini, prvoklasna usluga, vrhunska kvaliteta, svjetski poznato

1. Učinak razmjera: Naša tvrtka ima veliki lanac opskrbe i veliku tvornicu čelika, postižući učinke razmjera u transportu i nabavi te postajući čelična tvrtka koja integrira proizvodnju i usluge

2. Raznolikost proizvoda: Raznolikost proizvoda, bilo koji čelik koji želite možete kupiti od nas, uglavnom se bavimo čeličnim konstrukcijama, čeličnim tračnicama, čeličnim šljuncima, fotonaponskim nosačima, kanalnim čeličnim profilima, zavojnicama od silicijskog čelika i drugim proizvodima, što ga čini fleksibilnijim. Odaberite željenu vrstu proizvoda kako biste zadovoljili različite potrebe.

3. Stabilna opskrba: Stabilnija proizvodna linija i lanac opskrbe mogu osigurati pouzdaniju opskrbu. To je posebno važno za kupce kojima su potrebne velike količine čelika.

4. Utjecaj brenda: Imaju veći utjecaj brenda i veće tržište

5. Usluga: Velika čelična tvrtka koja integrira prilagodbu, transport i proizvodnju

6. Konkurentnost cijena: razumna cijena

*Pošaljite e-poštu na[e-pošta zaštićena]kako biste dobili ponudu za svoje projekte

POSJET KUPACIMA